Home >

News > Optimisation of the synthesis of MOF nanoparticles made of flexible porous iron fumarate MIL-88A

Optimisation of the synthesis of MOF nanoparticles made of flexible porous iron fumarate MIL-88A

Summary:

The authors from Université Paris-Sud, Université de Versailles Saint-Quentin developed MIL-88A nanoparticles, a flexible porous iron fumarate MOF, with small size, good monodispersity, and high yield, achieving optimized synthesis for potential biomedical and other applications.

Background:

1. Metal-organic frameworks (MOFs) have promising applications, but synthesizing small, monodisperse MOF nanoparticles with non-toxic solvents and high yields is challenging. Previous methods often involve toxic solvents, long reaction times, or result in low yields and polydisperse particles.

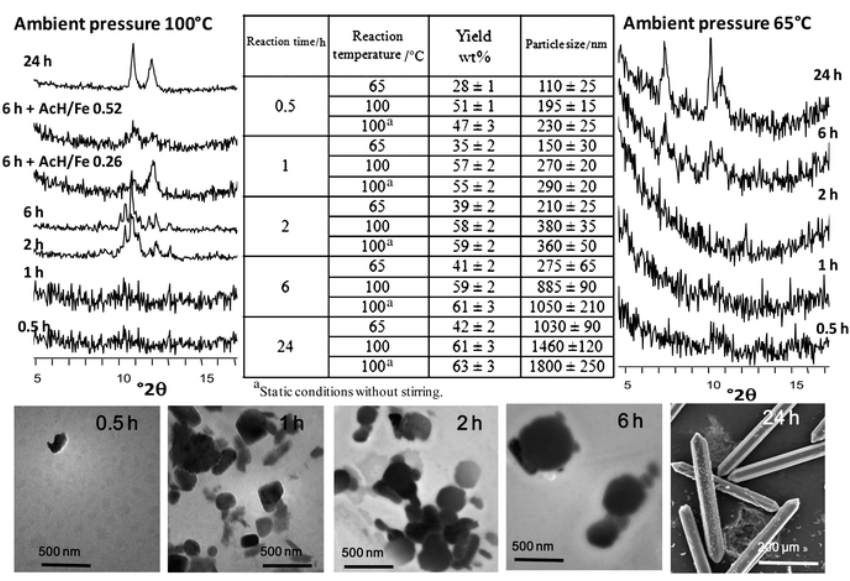

2. The authors compared various synthesis methods (solvothermal, hydrothermal, ultrasonic, microwave-assisted) to optimize the synthesis of MIL-88A nanoparticles, successfully obtaining small, monodisperse particles with high yields using microwave-assisted hydrothermal synthesis.

Research Content:

1. Synthesis:

The authors synthesized MIL-88A using multiple methods. Solvothermal/hydrothermal methods used FeCl₃·6H₂O and fumaric acid in solvents like DMF, methanol, or water, under different temperatures and times. Ultrasonic synthesis employed aqueous solutions with varying temperatures, concentrations, and additives. Microwave synthesis used 1:1 molar FeCl₃·6H₂O and fumaric acid aqueous mixtures, heated by microwave irradiation (600 W) with controlled temperature, time, concentration, and pressure.

2. Characterizations:

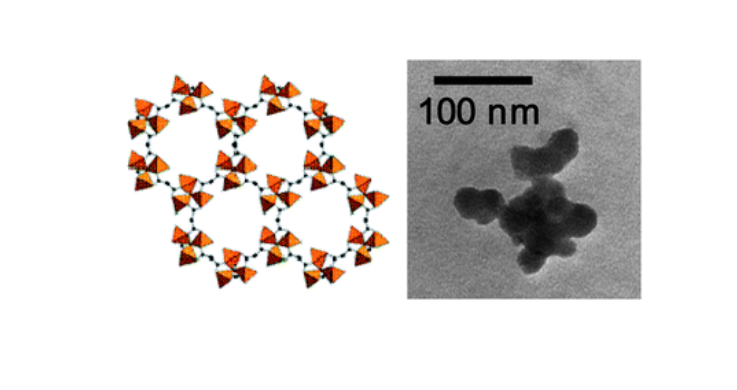

1) BET and pore size distribution data are not explicitly provided, but the material is a porous framework with interconnected pores and cages (5-7 Å).

2) SEM/TEM tests show that microwave-synthesized MIL-88A has small particle sizes: ~20 nm at 50°C for 2 min, ~100 nm at 80°C for 5 min, with good monodispersity (PDI < 0.20).

3) Other tests: X-ray powder diffraction (XRPD) confirmed the formation of MIL-88A; dynamic light scattering (DLS) measured particle size and polydispersity index (PDI).

3. Application:

The material's optimized synthesis lays the foundation for applications in biomedical fields (e.g., drug delivery, imaging) and other areas requiring porous nanoparticles, due to its biocompatibility, non-toxicity, and controllable particle size.

4. Mechanism:

Microwave synthesis enables rapid and homogeneous heating, creating local "hot spots" that overcome energy barriers, promoting fast and uniform nucleation. This results in small, monodisperse nanoparticles. Ultrasonic synthesis uses cavitational collapse for nucleation but yields low. Solvothermal/hydrothermal methods often lead to larger, polydisperse particles due to uneven heating and coalescence growth.

Outlook:

This research optimizes the synthesis of MIL-88A nanoparticles, demonstrating that microwave-assisted hydrothermal synthesis is efficient for producing small, monodisperse, high-yield MOF nanoparticles, which is significant for their large-scale production and application in biomedicine and beyond.

Optimisation of the synthesis of MOF nanoparticles made of flexible porous iron fumarate MIL-88A

Authors: T. Chalati, P. Horcajada, R. Gref, P. Couvreur, C. Serre

DOI: 10.1039/c0jm03563g

Link: https://pubs.rsc.org/en/content/articlelanding/2011/jm/c0jm03563g

The above review is for academic progress sharing. For any errors or copyright issues, please contact us for correction or removal.